Home

Product

WEF series four shaft shredder

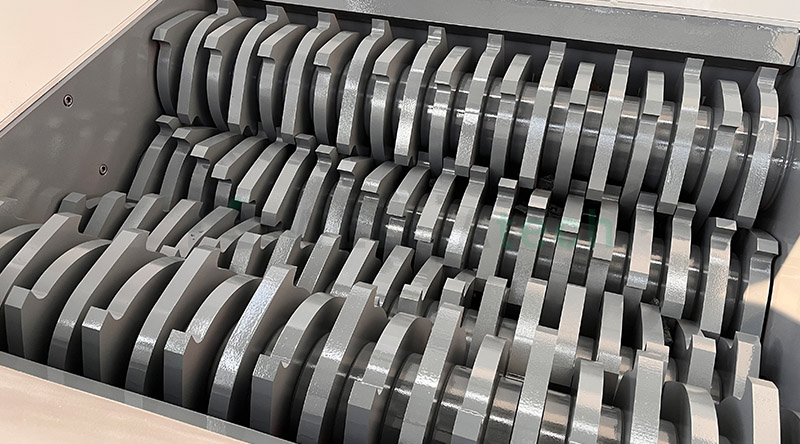

WEF series four shaft shredder materials through the combined forces of tearing, crushing, and shearing by the blades, breaking them into smaller pieces. When the material size is smaller than the screen mesh openings, it is discharged through the lower screen holes under gravity and extrusion force. Larger materials remain in the crushing chamber and continue to be processed until their size meets the screen mesh requirements.

Capacity :1t-10t/h

Output Size:30-50mm

Four Shaft Shredder_WEF Series

WhatsApp1

WhatsApp2

Output Display

WEF Series-Overview

Materials:

- E-Waste: Shredding discarded computers, televisions, and other electronics

- to facilitate the subsequent recovery of metals and plastics.

- Industrial Waste: Processing plastic barrels, ton bags, large rolls of film,

- fibers, and paper mill waste.

- Solid Waste (SRF/RDF): Treating municipal solid waste to produce

- uniformly-sized fuel pellets.

- Scrap Metal: Shredding automotive shells, waste aluminum profiles, oil

- drums, and home appliance housings.

- Tires: Shredding whole tires into rubber chips for use in recycled rubber,

- oil refining, or as fuel.

- Hazardous Waste: Enabling the harmless treatment and volume reduction

- of waste paint drums, chemical packaging barrels, and similar materials.

E-Waste: Shredding discarded computers, televisions, and other electronics

to facilitate the subsequent recovery of metals and plastics.

Industrial Waste: Processing plastic barrels, ton bags, large rolls of film,

fibers, and paper mill waste.

Solid Waste (SRF/RDF): Treating municipal solid waste to produce

uniformly-sized fuel pellets.

Scrap Metal: Shredding automotive shells, waste aluminum profiles, oil

drums, and home appliance housings.

Tires: Shredding whole tires into rubber chips for use in recycled rubber,

oil refining, or as fuel.

Hazardous Waste: Enabling the harmless treatment and volume reduction

of waste paint drums, chemical packaging barrels, and similar materials.

Material is fed into the crushing chamber via a conveyor belt or manually. Within the two shearing zones formed by the four rotating shafts, the material is repeatedly subjected to shearing, compression, tearing, and stretching, thereby being fragmented. The shredded material falls through the bottom screen by gravity and is transported away by the conveyor belt below. Any material that does not meet the required size specifications remains in the chamber for continued shredding.

Working Principle

WEF Series-Features

Screen

Uniform Discharge | Adjustable Output Size | Easy & Quick Maintenance

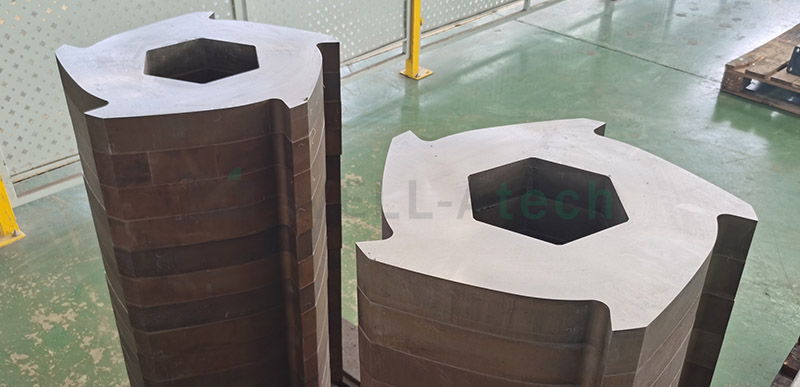

Rotor Blade

DILLIGUR / HARDOX丨Imported NiCrMo High-Alloy Steel | Hardfacing Repair

Multi-Cutting

4 Cutter Shafts | Multi-Shearing | High Crushing Efficiency | Anti-Bridging Design

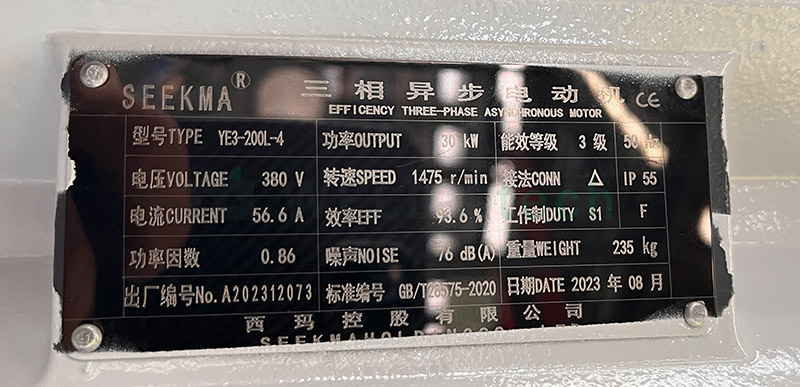

Motor

Top-Tier Motor | Low Noise | High Efficiency & Energy Saving | Superior Stability

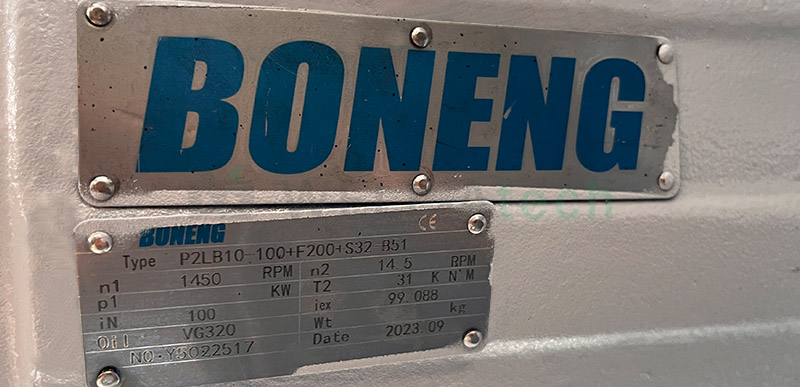

Planetary Gearbox

High Transmission Efficiency | Smooth Operation | High Load Capacity | Excellent Impact & Shock Resistance

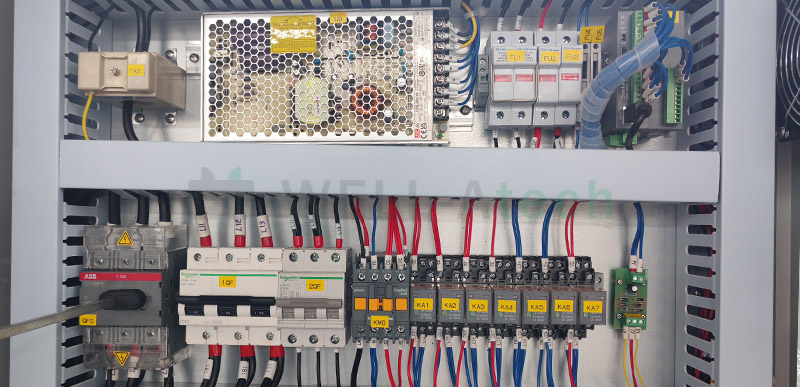

Electrical Control

PLC Automation Control | Current Monitoring | Overload Protection | Auto-Reversal | Emergency Stop

Full machine warranty for one year (excluding wear parts), with lifetime after-sales support!

WEF Series-Parameters

| Specification | WEF800 | WEF1000 | WEF1200 | WEF1400 | WEF1600 |

| Crushing chamber(mm) | 800*600 | 1000*900 | 1200*1000 | 1400*1300 | 1600*1600 |

| Motor power (kW) | 2*11 | 2*18.5 | 2*22 | 2*15+2*30 | 2*30+2*45 |

| Rotor diameter (mm) | φ245 | φ290 | φ320 | φ430 | φ534 |

| Rotating speed(r/min) | 16-25 | 16-25 | 16-25 | 10-15 | 10-15 |

| L*W*H Dimension(mm) | 1950*1200*2065 | 2300*1320*3000 | 2810*1400*2730 | 3600*1650*2930 | 4360*2200*3630 |

| Voltage and color customization available | |||||